Description

CINA Laser’s CYL-2000/S 1.0μm single-mode group continuous fiber laser, adopts latest industry technology and the optimization design, with high electro-optical conversion efficiency, high lifetime, high safety and reliability. The unit with high-quality output beam and strong capability on resisting high-reflective, can be widely used in all kinds of materials of laser cutting, welding, punching, 3D printing and other high-end smart manufacturing.

CINA Laser, which is based on Internet technology, established a scientific after-sales service system. Each device has a unique identity code (the internal storage of original technology and material information). Can achieve remote online real-time monitoring; can provide users with equipment fault early warning and efficient technical support and good after-sales service.

CINA Laser’s products with high quality, high reliability and excellent cost performance, can meet the requirements of the customer diversification and personalized customization. It also with good after-sales service, is the ideal choice for system integrates and equipment manufacturers.

CINA Laser, which is based on Internet technology, established a scientific after-sales service system. Each device has a unique identity code (the internal storage of original technology and material information). Can achieve remote online real-time monitoring; can provide users with equipment fault early warning and efficient technical support and good after-sales service.

CINA Laser’s products with high quality, high reliability and excellent cost performance, can meet the requirements of the customer diversification and personalized customization. It also with good after-sales service, is the ideal choice for system integrates and equipment manufacturers.

Features

◉ High electro-optical conversion efficiency, greatly reduced the power consumption

◉ Strong capability on resisting high-reflective, suitable for different materials processing.

◉ Remote real-time monitoring.

◉ High lifetime, high safety and reliability.

◉ Can achieve personalized customization.

◉ Excellent after-sales service system.

◉ Excellent cost performance

Applications

◉ Laser cutting.

◉ Laser welding.

◉ Laser cladding.

◉ Laser brazing.

◉ Laser thermolizing.

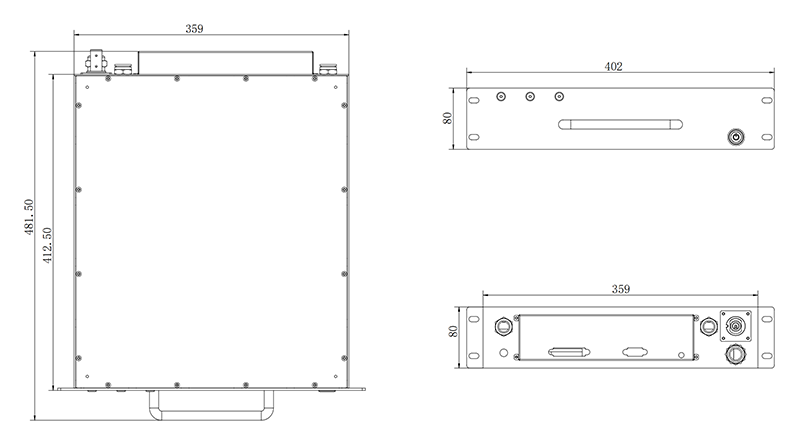

Size

Technical Index

| Performance | Min. | Typ. | Max. | Supplement | ||

| Optic Feature | Central wavelength | (nm) | 1070 | 1080 | 1090 | |

| Spectral bandwidth | (nm) | 3 | 5 | -3dB | ||

| Output optical power | (W) | 2000 | ||||

| Power ADJ. range | (%) | 10 | 100 | |||

| Output power stability | (%) | 1 | 1.5 | 100% continuous >1h | ||

| 2 | 3 | 100% continuous >24h | ||||

| Beam quality | (BPP) | 1.3 | QBH-20/400 | |||

| 2.8 | QBH-50/360 | |||||

| Modulation frequency. | (KHz) | 20 | 100% output | |||

| Glow power | (mW) | 0.3 | 1.0 | |||

| Output Feature | Output connector | QBH | Customize | |||

| Output fiber core-diameter | (μm) | 20 | 100 | |||

| Output fiber length | (m) | 15 | Customize | |||

|

Output fiber l bending radius |

(mm) | 200 | ||||

| Working mode | Continuous modulation | CW/Modulate | ||||

| Polarization state | Random | Random | ||||

|

Electrical cooling Feature |

Telecommunication port | RS232 / AD / Super terminal | ||||

| Remote telecommunication | APP | Customize | ||||

| Power supply | (V) | 340 | 380 | 420 | Three phase five wire | |

| Power consumption | (KW) | 6.0 | ||||

| Cooling method | Water-cooling | Circumscribed | ||||

| Coolant temp. | (°C) | 21 | 25 | |||

| Coolant flow | (L/min) | 25 | ||||

| General Feature | Working environment temp. | (°C) | 10 | 40 | ||

| Working environment humidity | (%) | 10 | 85 | |||

| Storage temp. | (°C) | -10 | 60 | |||

| Weight | (kg) | 23.5 | ||||

| Structure | Machine cabinet | |||||

| Size (W) × (L) × (H) | (mm) | 402 (359)x481.5(412.5)x80 | (W)with Handle×(L) with Handle×(H) | |||

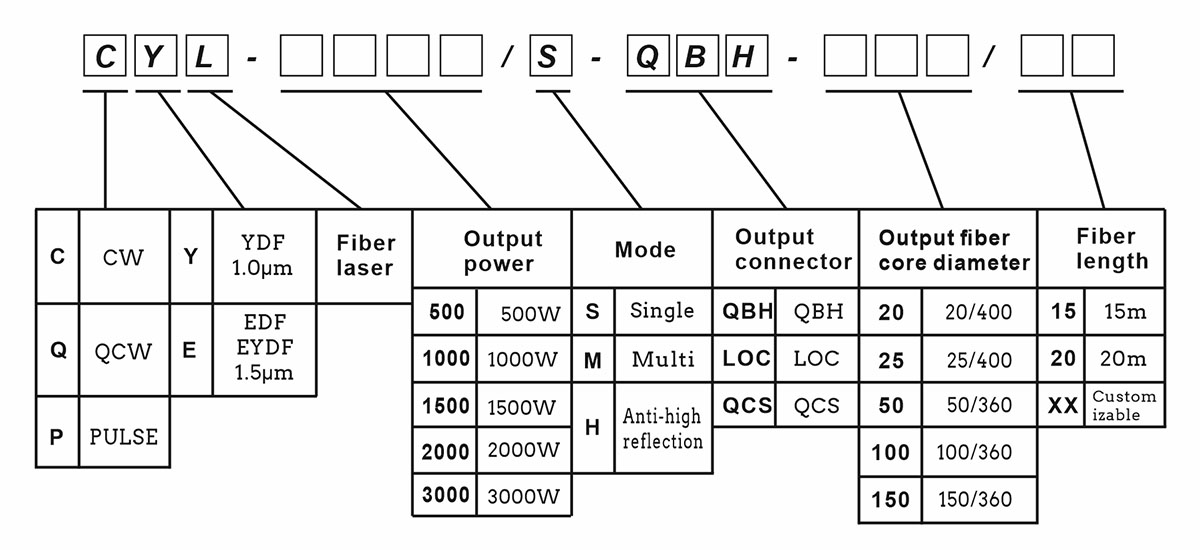

Model Explanation

CINA Laser

CINA Laser

CINA Laser

CINA Laser

1A, Building1, 7 Xiyuan Rd, Hangzhou 310030, China

1A, Building1, 7 Xiyuan Rd, Hangzhou 310030, China